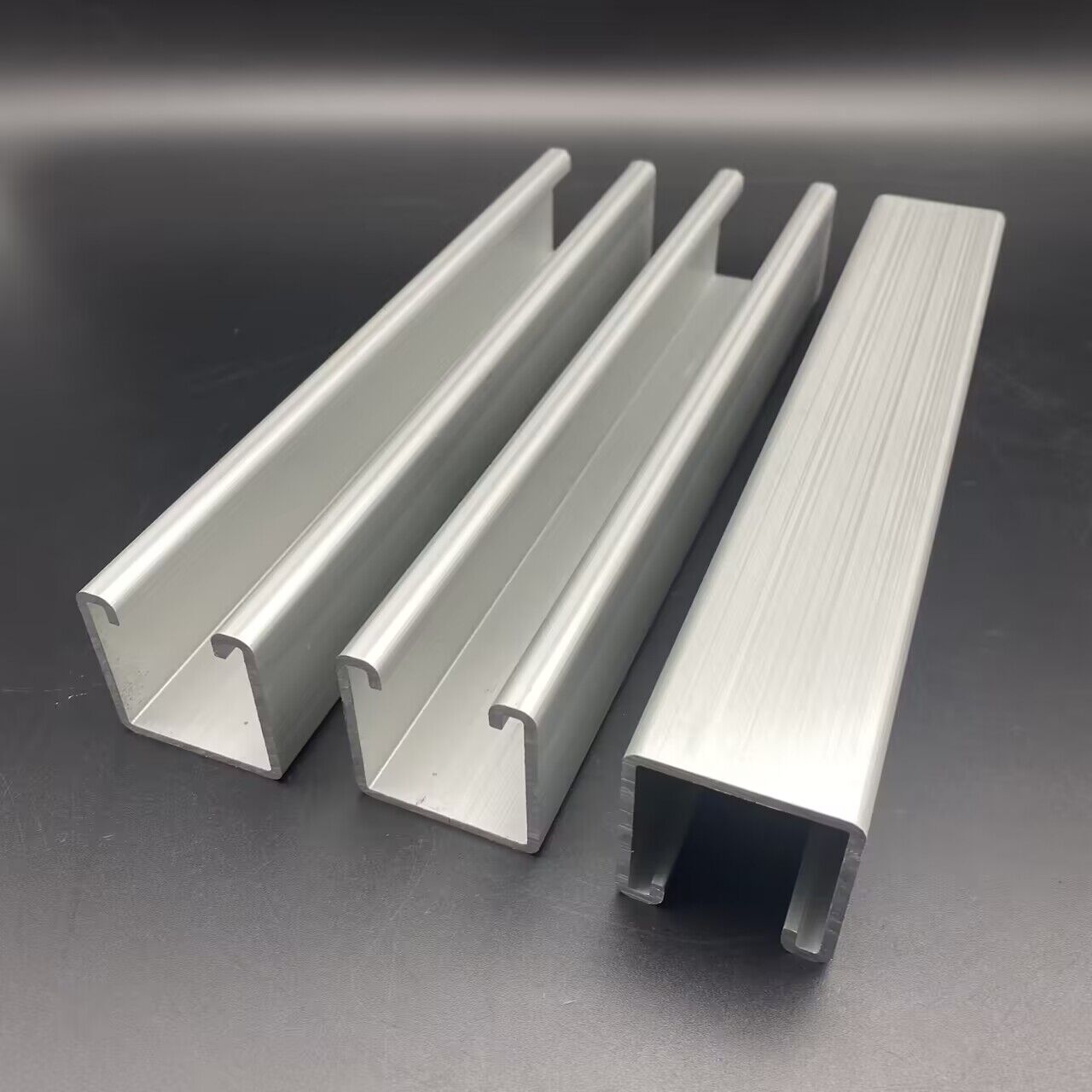

C channels, commonly referred to as C-sections or C-profiles, are structural elements that are frequently employed in industrial and construction settings. Their shape, which resembles the letter "C" when examined in cross-section, gave rise to their name. A web connects the flanges on top and bottom of C channels, which are commonly composed of steel or aluminum.

Features:

C channels are suited for applications requiring structural support without added weight since they are lightweight while still having great strength.

C channels are resistant to bending and twisting forces because of their structure, which offers strong torsional rigidity.

C channels are cost-effective than other structural alternatives.

They give versatility in installation and assembly since they are simple to weld, bolt, or connect with other fitting parts,such as spring nuts,rod stiffener,pipe clamp etc.

Various industries use C channels

Structure support in building construction, such as framing walls and roof system.

Shelves and racks in commercial and industrial facilities for storage providing support and bracing.

Provides a foundation for the installation of electrical conduit in building infrastructure.

Improvement in the production of machines and automobiles.

I beams, often referred to as H beams or universal beams, are steel structural members with cross-sections that resemble the letter "I." It hans a vertical web in the central that connects the horizontal top and bottom flanges. I beams are made to sustain structures across its wide span and bear severe loads.

Strength and Advantages

I beams are appropriate for heavy-duty applications and extended spans due to their superior load-bearing qualities.

Their symmetrical construction offers consistent support and distributes the load equally throughout the beam.

I beams reduce deflection and deformation under severe loads through offering structural rigidity and stability.

They may be built to withstand changing forces like vibrations.

I beams are widely used in construction and engineering applications

Support beams used in the construction of buildings, such as high-rise building columns and beams.

Long-span structural elements are needed for infrastructure projects like bridges.

Applications used in industry, such as crane rails and overhead gantries.

Commercial spaces with mezzanine levels and platforms.

Compare with C Channel and I Beam

A.Load-Bearing Capabilities and Structural Features

Both C channels and I beams can support loads, but each has advantages over the other:

Lighter loads and shorter spans are more suited for C channels. In applications that don't need for a lot of load-bearing capability, they offer adaptability.

Projects needing heavy loads, lengthy spans, and substantial structural support are where I beams stand out. They are preferred for industrial uses and huge construction projects.

B. Versatility and Flexibility in Design

C channels and I beams have different levels of design adaptability and versatility:

C channels provide greater flexibility in design since they are simple to cut, weld, or mold into different configurations, allowing them to be adapted to meet the requirements of a particular job.

I beams have a specified shape and come in a range of sizes, providing numerous design options. However, Compared to C channels, it may be more difficult to change their shape.

C. Installation and User-Friendliness

Considering that C channels are lighter, they are more manageable and simpler to install. They can be fastened with bolts, joined together using welding, or suspended using brackets or hangers.

I beams may need specialist tools and knowledge to be installed because they are heavier and more durable. In order to successfully complete construction projects, their size and weight require meticulous planning and coordination.

In Conclusion, when you make a decision between c channels and I beams, considering structural requirements overall, the span lengths, and the load criteria. Budget constraints, evaluate the financial effects of each choice, taking into account material, fabrication, and installation costs. And environmental conditions, evaluate how the performance and durability of the selected structural component are affected by factors including weather, temperature, corrosion, and other external forces.